Free Pole Barn Material Calculator Online

Building a pole barn isn’t just about hammering posts into the ground—it’s about precision, planning, and smart material usage. Whether you’re constructing a small backyard shed or a full agricultural barn, using a pole barn material calculator ensures you stay within budget, minimize waste, and account for every detail. From foundation materials to roof area, Construction Calculators help DIYers and contractors alike estimate everything from lumber and joists to insulation and wall framing.

In this in-depth guide, we’ll explore how the pole barn material calculator works, what inputs you need, and how to apply the results to real-world projects. We’ll also include key formulas, examples, and a breakdown of critical elements like floor size, shed dimensions, and cost estimates. Whether you’re focused on construction budgets or just looking to save time, this blog has it covered.

Pole Barn Material Calculator

What Is a Pole Barn Material Calculator?

A pole barn material calculator is an online tool designed to estimate the exact quantity of materials needed for building a pole barn structure. It factors in dimensions like length, width, height, and roof pitch to generate a comprehensive material list, including lumber, wall framing, joists, metal panels, and foundation supplies. This tool simplifies planning for both DIY builders and construction professionals, helping you avoid over-purchasing and budget surprises.

Why You Need a Pole Barn Material Calculator

Every construction project needs accurate material lists. A pole barn material calculator delivers instant estimates for:

- Total material cost

- Wall and roof area

- Board footage

- Footage of framing lumber

- Insulation coverage

- Amount of siding and metal roofing

Instead of rough guesses, you get precise numbers that align with your barn’s dimensions, design, and floor area. Whether you’re building in feet, meters, or using square footage, a calculator simplifies complex calculations into clear, actionable totals.

Inputs Required for Accurate Calculations

To generate accurate results, you’ll need to input several key project details:

- Length, width, and height of the pole barn

- Number of wall sections (gable and eave sides)

- Roof pitch or slope

- Door and window dimensions

- Type of materials (metal, wood, etc.)

- Desired insulation thickness

- Joist spacing and wall stud layout

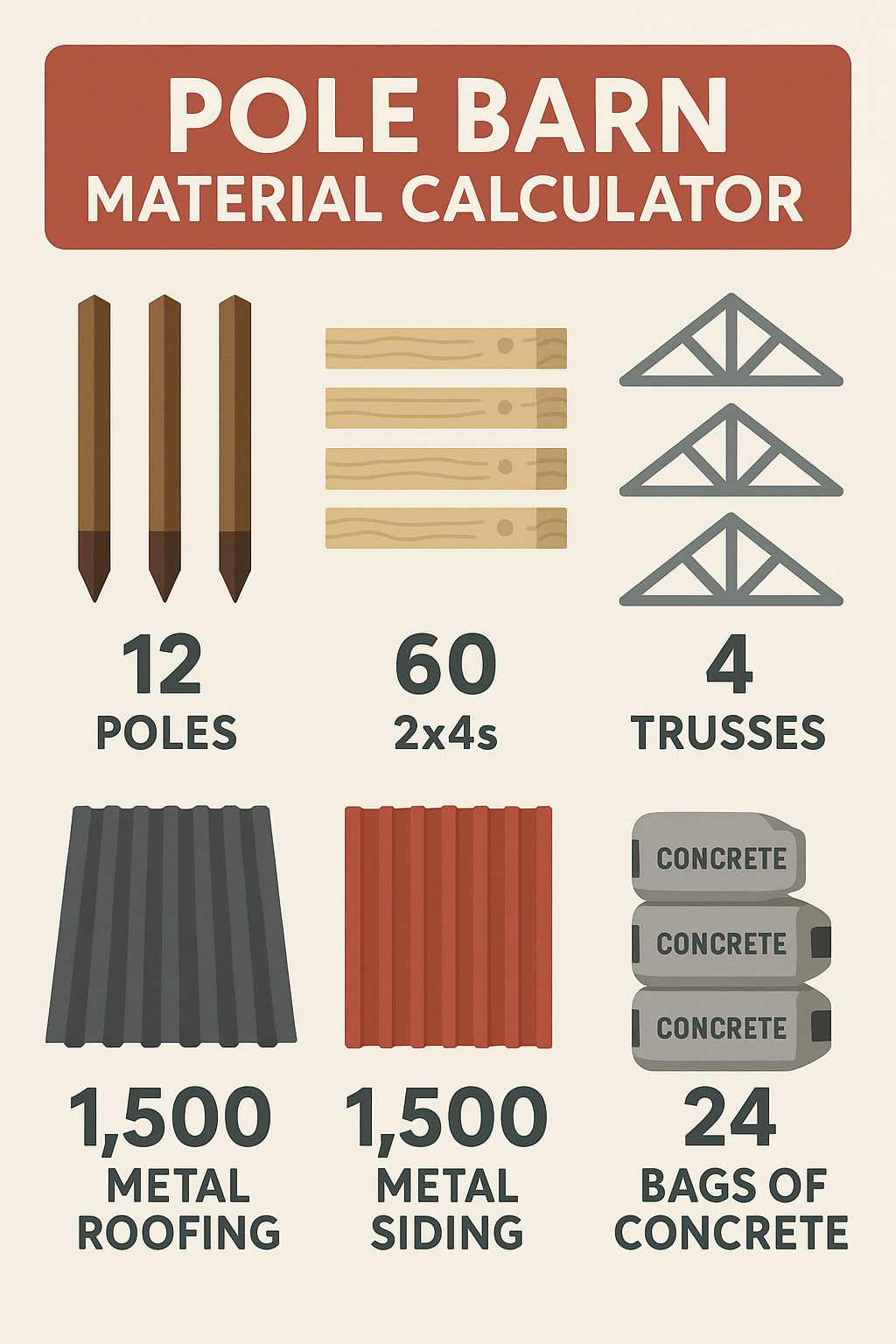

The calculator then compiles a material list, including:

- Number of poles

- Linear footage of headers and girts

- Square footage of roofing

- Siding panels

- Volume of concrete for footers

- Sheets of plywood or OSB

- Rolls or batts of insulation

Formulas Behind the Calculator

Here are a few formulas commonly used by a pole barn material calculator:

Wall Area Formula $$[

\text{Wall Area} = \text{Wall Length} \times \text{Wall Height}

]$$

Roof Area for Gable Roofs $$\text{Roof Area} = \text{Building Length} \times \text{Roof Slope Factor} \times 2$$

Total Square Footage of Building $$Square Footage=Length×Width\text{Square Footage} = \text{Length} \times \text{Width}Square Footage=Length×Width$$

Board Feet Formula for Lumber $$\text{Board Feet} = \frac{\text{Thickness (in)} \times \text{Width (in)} \times \text{Length (ft)}}{12}$$

Insulation Needs $$[

\text{Insulation Area} = \text{Wall Area} + \text{Ceiling Area} – \text{Door/Window Area}

]$$

These calculations help you determine how many boards, panels, and rolls you need. That means no material shortages, no cost overruns, and fewer wasted resources.

Estimating Wall, Roof, and Floor Areas

When planning a pole barn, your wall square footage, roof coverage, and floor area must all be accurate. This is particularly important when ordering:

- Wall siding

- Roof metal sheets

- Flooring material

- Concrete for slabs

These figures become the basis of your material list and budget calculator output.

Budgeting With a Material Calculator

Once you have your material estimates, you can start applying unit costs. For example:

- Plywood sheathing: $25/sheet

- Metal roofing: $3/sq ft

- Lumber: $0.90/board foot

- Concrete: $135/cubic yard

- Insulation: $0.65/sq ft

A pole barn material calculator often integrates these market prices, giving you an immediate project cost estimate. The calculator can adjust for:

- Regional prices

- Delivery rates

- Labor multipliers

- Waste percentage (typically 5-10%)

This keeps you prepared for unexpected fluctuations in costs, especially when dealing with supply and demand volatility or planning deliveries across North America.

Benefits of Using the Calculator

- Accuracy in Quantity Estimation

Avoid material shortages by ordering the correct number of boards, panels, and fasteners. - Time-Saving for DIYers and Contractors

Eliminate manual calculations and get instant material lists with total costs. - Supports Budget Planning

Combine standard pricing with your list for accurate cost estimates and project proposals. - Improves Efficiency in Freight Planning

Know exactly how many pallets or truckloads you’ll need to ship materials. - Eliminates Guesswork

Helps reduce waste and overordering with precise square foot calculations. - Adapts to Project Changes

Recalculate in seconds when barn size, pitch, or material type changes.

Key Elements to Track

When reviewing your output from a pole barn material calculator, verify the following:

- Roof pitch matches building plans

- All door/window openings are deducted from wall area

- Interior partitions included if needed

- Exact number of poles, trusses, and purlins

- Sufficient bracing and fasteners included

- Surcharge for shipping to remote areas like Alaska or Puerto Rico

For large projects, calculators may also show:

- Pallet count

- Weight per truckload

- Delivery timelines

- Estimated labor hours

These details are especially useful when working with construction supply companies, scheduling freight deliveries, or coordinating with customer service departments.

Common Mistakes Avoided with a Calculator

- Forgetting to Account for Overhangs

Affects both roofing material and drip edge length. - Incorrect Board Footage on Framing Lumber

Leads to over-purchasing or jobsite delays. - Missing Insulation Coverage for Gable Ends

Causes discomfort and higher utility costs. - Not Deducting Door/Window Area from Walls

Results in inflated material costs. - Underestimating Waste

Every calculator should include a 5-10% waste margin depending on cuts.

Who Uses Pole Barn Material Calculators?

- DIY Builders designing sheds, garages, or small barns

- Contractors bidding on agricultural buildings

- Developers planning storage structures on large tracts

- Warehouse managers coordinating material freight deliveries

- Construction estimators verifying ratios and delivery schedules

Because these tools can export data into spreadsheets, they integrate seamlessly into project management workflows, freight shipping quotes, and material takeoff software.

Frequently Asked Questions (FAQs)

Q: Can this calculator handle metric units?

A: Yes, most advanced calculators support feet, inches, meters, and centimeters.

Q: Is labor included in the cost estimate?

A: Not typically. This tool focuses on material costs, but you can add standard labor rates separately.

Q: Can it estimate time to complete construction?

A: While not directly, the material scope helps determine labor hours based on structure size.

Q: Can I customize inputs like joist spacing?

A: Yes. You can modify spacing, wall height, roof pitch, and more for tailored results.

Summary

A pole barn material calculator is a game-changer for planning any building project. It enables builders to accurately estimate:

- Material quantities

- Total area

- Estimated cost

- Shipping volume

- Board footage

From floor to roof, every element can be estimated using common General Construction Calculators principles. This leads to better project control, tighter budgets, and improved jobsite management. Whether you’re shipping across North America or constructing locally, using tools like the Stair Calculator or Welding Calculator means less stress and fewer surprises.

Final Table of Common Formulas

| Purpose | Formula |

|---|---|

| Wall Area | $$Wall Length × Wall Height$$ |

| Roof Area | $$Building Length × Roof Slope Factor × 2$$ |

| Floor Area | $$Length × Width$$ |

| Board Feet | $$(Thickness × Width × Length) ÷ 12$$ |

| Insulation Area | $$Wall + Ceiling Area – Door/Window Area$$ |

| Plywood Sheets Needed | $$Total Sq Ft ÷ 32$$ |

| Waste Margin | $$Total Material × 1.10$$ |