Free Asphalt Emulsion Calculator Online

When working on road construction, resurfacing, or full-depth reclamation, applying the correct amount of asphalt emulsion is critical to project success. An Asphalt Emulsion Calculator from Construction Calculators allows contractors, engineers, and estimators to determine the proper emulsion volume required for a specific project area based on application rate, surface dimensions, and emulsion content. This tool ensures you apply the correct quantity, reduce material waste, and meet roadway performance standards.

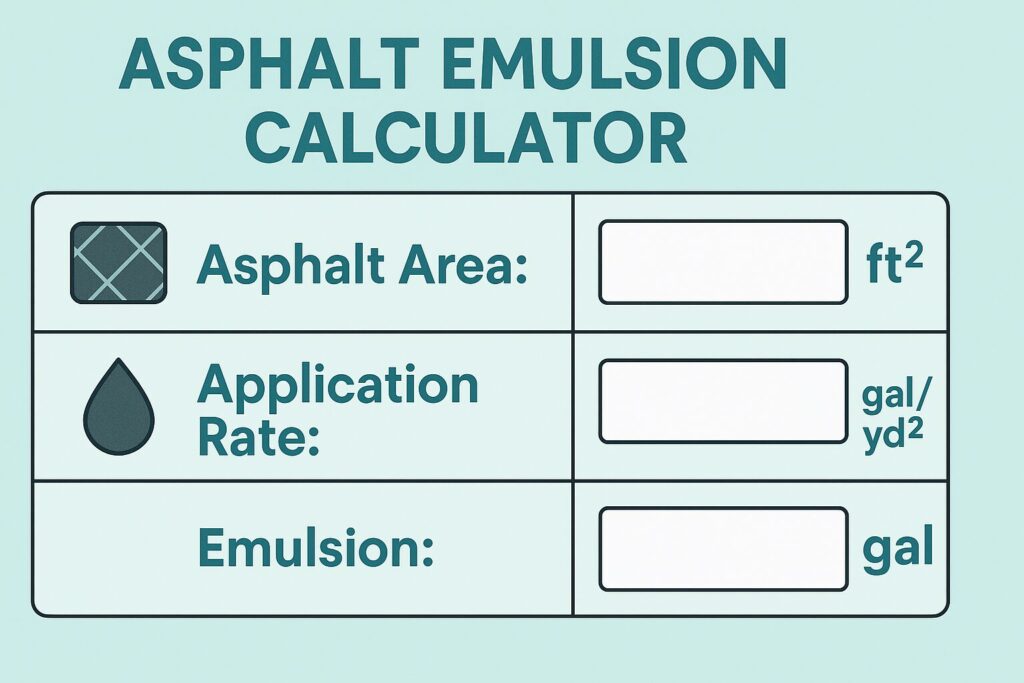

What Is an Asphalt Emulsion Calculator?

An Asphalt Emulsion Calculator is a digital tool or formula-driven system that estimates the total gallons or tons of asphalt emulsion needed for a given surface area. Whether you’re applying a tack coat, prime coat, or working on base stabilization with emulsified asphalt, this calculator helps streamline material planning. It’s especially useful for DOT jobs, pavement overlays, or stabilized base layers requiring precise bitumen distribution.

Core Inputs of the Emulsion Calculator

To use the calculator effectively, you’ll need the following values:

1. Application Rate (gal/yd² or gal/ft²)

This is the amount of asphalt emulsion applied per unit area. It depends on the type of work:

- $$Tack coat: 0.05–0.10 gal/yd²$$

- $$Prime coat: 0.20–0.50 gal/yd²$$

- $$Full-depth reclamation: 0.25–1.00 gal/yd²$$

2. Emulsion Residue Percentage (%)

This refers to the asphalt content in the emulsion. Common emulsions like SS-1 or CRS-2 typically have 60% to 70% asphalt residue. The remaining percentage is water or other additives.

3. Total Surface Area (in square feet or square yards)

This is the total area where emulsion will be applied. Use site measurements or scaled drawings. $$\text{Area (SY)} = \frac{\text{Length (ft)} \times \text{Width (ft)}}{9}$$

Asphalt Emulsion Volume Formula

To calculate the required emulsion volume in gallons: $$\text{Total Emulsion (gal)} = \text{Application Rate (gal/SY)} \times \text{Area (SY)}$$

To calculate the asphalt binder residue: $$\text{Asphalt Residue (gal)} = \text{Total Emulsion (gal)} \times \left( \frac{\text{Residue \%}}{100} \right)$$

Example Calculation

Let’s say you’re applying a prime coat at 0.30 gal/yd² over a 12,000 ft² area using an emulsion with 65% asphalt residue.

Step 1: $$\frac{12,000}{9} = 1,333.33 \text{ SY}$$

Step 2: $$Calculate total emulsion required 0.30×1,333.33=400 gallons0.30 \times 1,333.33 = 400 \text{ gallons}0.30×1,333.33=400 gallons$$

Step 3: $$400 \times 0.65 = 260 \text{ gallons of asphalt residue}$$ residue}400×0.65=260 gallons of asphalt residue

Advanced Considerations: Tons Instead of Gallons

If the job spec calls for tons instead of gallons:

Use this conversion: $$Weight (tons)=Gallons×8.342000\text{Weight (tons)} = \frac{\text{Gallons} \times 8.34}{2000}Weight (tons)=2000Gallons×8.34$$

Where 8.34 is the average weight of one gallon of emulsion in pounds. Example: $$400×8.342000=1.67 tons\text{Example: } \frac{400 \times 8.34}{2000} = 1.67 \text{ tons}Example: 2000400×8.34=1.67 tons$$

Factors That Affect Application Rate

Several job-specific and environmental factors influence how much emulsion should be applied:

- Surface Type: Concrete, aggregate base, or recycled asphalt

- Weather Conditions: Temperature and humidity affect evaporation rate

- Traffic Load: Heavier traffic requires stronger or thicker bonding

- Absorption: Porous surfaces may require higher application rates

- Overlay Type: Hot mix asphalt (HMA), cold mix, or chip seal

Types of Asphalt Emulsions

There are multiple categories of asphalt emulsions used depending on job type:

- SS-1 / SS-1h: Slow-setting for tack coats and fog seals

- RS-2 / CRS-2: Rapid-setting for chip seals and surface dressing

- CSS-1 / CSS-1h: Cationic slow-setting for better adhesion

- AE-P: Asphalt emulsions for stabilization in full-depth reclamation

Benefits of Using an Asphalt Emulsion Calculator

Using an emulsion calculator helps in:

- Avoiding under- or over-application

- Maintaining project budgets and schedules

- Supporting documentation for bids and estimates

- Ensuring DOT or spec compliance

- Planning truckloads and tank storage volumes

Project Planning with Emulsion Volumes

Estimating total gallons also aids in delivery scheduling:

- Tanker trucks typically carry 5,000–6,000 gallons

- For smaller jobs, distributor tanks range from 500–1,000 gallons

- You can break down your pour by day, section, or lane

Field Tips for Applying Asphalt Emulsion

- Always calibrate distributor truck before application

- Ensure uniform spray pattern with proper nozzle angles

- Avoid applying emulsion during rainfall or low temperatures

- Allow for curing/drying time before overlay or traffic return

- Test surface temperature to ensure proper bonding

Frequently Asked Questions

Can I use this calculator for chip seals?

Yes. Just use a higher application rate (typically 0.35–0.50 gal/yd²).

Does the calculator account for evaporation?

No. The calculator gives the full emulsion amount; evaporation is handled in field application timing.

How do I choose the right emulsion type?

Refer to your DOT or job specs, or consult the emulsion supplier for local recommendations.

Is emulsion affected by cold weather?

Yes. Most emulsions should be stored and applied above 50°F to ensure proper break and curing.

How can I measure the actual application rate on-site?

Use the tank calibration chart and total spray distance to verify gallons per square yard.

Conclusion

An Asphalt Emulsion Calculator is an essential tool for accurate material planning and execution in any paving or stabilization project. By calculating the correct emulsion volume and asphalt residue, you ensure that your job meets engineering specs, avoids waste, and supports durable, long-lasting surfaces. Whether you’re working with tack coats, prime coats, or full-depth base stabilization, using this calculator will keep your project running smoothly from the start. Available on the Concrete Calculators platform, it complements other jobsite tools like the Rebar Spacing Calculator and the Concrete Paver Calculator to ensure total material control and construction precision.