Free Sealant Calculator Online

When tackling any caulking or sealing project—whether it’s windows, bathtubs, tile joints, expansion gaps, or perimeter seams—accurate material estimation is critical. A sealant calculator makes it easy to determine how much sealant you need, avoiding overbuying or running short halfway through the job. From home renovation professionals to DIYers, this tool ensures you’re working with the right amount of product, every time. Construction Calculators offers reliable tools to help you calculate sealant needs with speed and precision.

What Is a Sealant Calculator?

A sealant calculator is a project estimation tool that helps you calculate the total quantity of sealant or caulk required for your job based on joint dimensions, gap length, and bead size. This ensures efficient material use and accurate ordering for sealing projects across various industries construction, plumbing, waterproofing, and interior finishing.

The calculator factors in the width, depth, and length of all sealant joints to estimate linear feet, milliliters, or cartridge count needed. Using this tool simplifies planning, keeps costs in check, and reduces material waste.

Key Measurements Needed

To use a sealant calculator effectively, you’ll need the following dimensions:

- Joint Width (W): The horizontal opening of the gap

- Joint Depth (D): How deep the sealant needs to fill

- Joint Length (L): The full length of the joint to be sealed

- Number of Joints (N): Total quantity of identical joints in the project

These inputs form the basis for the total sealant volume and product quantity.

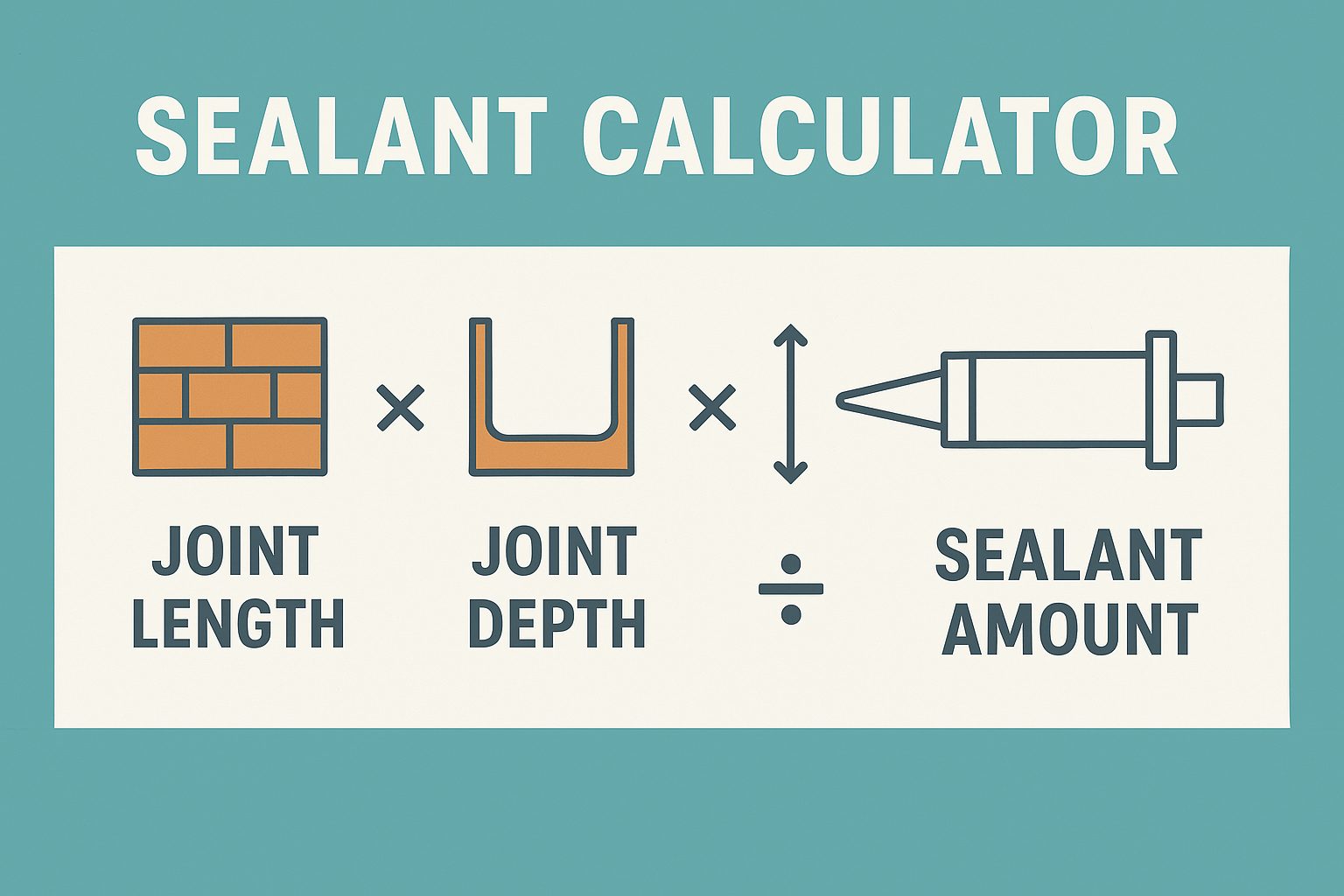

Formula to Calculate Sealant Volume

The formula for calculating the volume of sealant required is: $$\text{Volume (cubic inches)} = W \times D \times L$$

To convert this to milliliters (ml): $$\text{Volume (ml)} = \text{Volume (in}^3\text{)} \times 16.387$$

Or to determine cartridges (standard cartridge = ~310 ml): $$\text{Number of Cartridges} = \frac{\text{Total Volume (ml)}}{310}$$

Always round up and add 5–10% for wastage, shrinkage, or tool cleaning.

Why Accurate Sealant Estimation Matters

Accurate sealant calculations help you:

- Avoid material shortage or project delays

- Eliminate unnecessary sealant tube purchases

- Stay within budget and avoid waste

- Ensure joint durability by applying proper sealant thickness

- Maintain structural integrity of windows, joints, or expansion seams

- Prevent water, dust, or air infiltration due to incomplete sealing

Especially for large or commercial sealing projects, misjudging material needs can lead to costly rework or inconsistent application.

Step-by-Step: How to Use a Sealant Calculator

Step 1: Measure Joint Dimensions

Measure the width, depth, and length of each joint or gap in inches or millimeters. For irregular joints, take average values.

Step 2: Enter the Number of Joints

Multiply the result by the number of identical joints needing sealing.

Step 3: Calculate Total Volume

Use the formula to get the total sealant volume in cubic inches or milliliters.

Step 4: Convert to Cartridges

Divide total milliliters by the volume of a single sealant tube (usually 300–310 ml).

Step 5: Round Up and Add Margin

Always round up to the next full cartridge and include a 5–10% safety margin.

Example Calculation

Let’s assume:

- Joint Width = 0.5 inches

- Joint Depth = 0.5 inches

- Joint Length = 96 inches (8 feet)

- Number of Joints = 4

$$\text{Volume per Joint (in}^3\text{)} = 0.5 \times 0.5 \times 96 = 24 \text{ in}^3$$

You’ll need 6 cartridges after rounding and including a small waste buffer.

Factors That Affect Sealant Quantity

1. Bead Shape

A triangular bead uses less material than a rectangular or concave one. Most calculators assume a simple rectangular cross-section unless specified.

2. Joint Movement

Expansion joints require flexible sealants and often deeper fills, increasing sealant quantity.

3. Surface Conditions

Porous materials like concrete may absorb more sealant. Apply a primer to reduce waste.

4. Application Method

Cartridge guns, bulk pumps, or sausages affect bead consistency. Uneven application can lead to overuse.

Sealant Types and Application Areas

Depending on your project, the sealant calculator applies across various types and materials:

- Silicone Sealant: Ideal for glass, ceramics, and bathrooms

- Polyurethane Sealant: Best for concrete, expansion joints, and outdoor use

- Acrylic Sealant: For indoor cracks and seams

- Hybrid Polymer Sealant: Multi-purpose, paintable, long-lasting

Common application areas:

- Bathroom tubs and showers

- Window and door perimeters

- Siding and flashing joints

- Expansion joints in slabs

- Pipe penetrations

- Roof flashing

- Glass-to-frame installations

Sealant Calculator for Construction Use

In large-scale construction, precision matters. Engineers use sealant calculators to:

- Estimate costs for bulk procurement

- Meet building code requirements

- Plan scheduling of sealant application

- Account for temperature expansion or load variation in joints

- Minimize downtime from under-supply

When working with curtain walls, concrete panels, or precast elements, exact volumes help avoid halts in project timelines.

Optimizing Your Sealant Application

To ensure optimal adhesion and long-term performance, keep the following best practices in mind:

- Clean surfaces thoroughly before applying

- Use appropriate backer rods for deep joints

- Apply sealant in consistent, even beads

- Tool the sealant to ensure full bond with surfaces

- Follow manufacturer’s coverage guidelines

Use the sealant calculator to pre-plan bead dimensions and ensure each joint is filled to the correct depth and thickness.

Metric vs Imperial – Unit Conversions

Depending on your region, the sealant calculator supports both metric and imperial measurements.

- 1 inch = 25.4 mm

- 1 cubic inch = 16.387 ml

- 1 foot = 0.3048 m

Ensure your units remain consistent throughout the calculation to avoid mistakes.

Sealant Wastage and Safety Margin

Professionals always plan for an extra 5–10% margin in material estimation. This accounts for:

- Application errors

- Irregular bead profiles

- Shrinkage upon curing

- Tooling loss

- Cartridge tip purging

Never plan your purchase down to the exact milliliter you’ll risk falling short.

Frequently Asked Questions (FAQs)

How do I know how many linear feet a tube of sealant will cover?

Use this formula: $$\text{Linear Feet} = \frac{\text{Cartridge Volume (ml)} \times 0.03937}{W \times D}$$

Example:

For 310 ml cartridge, 0.5-inch width and depth: $$\text{Linear Feet} = \frac{310 \times 0.03937}{0.5 \times 0.5} = 48.89 \text{ feet}$$

Can I use the same calculator for different sealant types?

Yes. While the physical coverage doesn’t change, curing time and adhesion differ. Follow manufacturer guidelines for best results.

Does temperature impact how much sealant I need?

Extreme temperatures can expand or contract joints. Add extra volume for outdoor applications in variable climates.

How many tubes do I need for a 100-foot expansion joint?

Use joint width and depth to determine volume, then convert to cartridges using the calculator. $$1 \times 0.5 \times 1200 = 600 \ \text{in}^3 = 9823.2 \ \text{ml} = \frac{9823.2}{310} \approx 32 \ \text{cartridges}$$

Can the calculator account for different bead shapes?

Most calculators assume rectangular beads. For triangular or concave shapes, apply a shape reduction factor (typically 0.5 to 0.7).

Conclusion

The sealant calculator is an indispensable tool for anyone working with gaps, joints, or seams. From bathrooms and windows to heavy-duty construction, estimating the correct amount of material keeps your project clean, efficient, and cost-effective. For a more complete material planning process, consider using the Board Foot Calculator, Cubic Yard Calculator, and Concrete Calculators alongside your sealant estimates.

By inputting just a few dimensions, you’ll get a detailed volume breakdown, know exactly how many cartridges to buy, and avoid surprises. It’s your simple solution to precise sealing saving time, materials, and money.