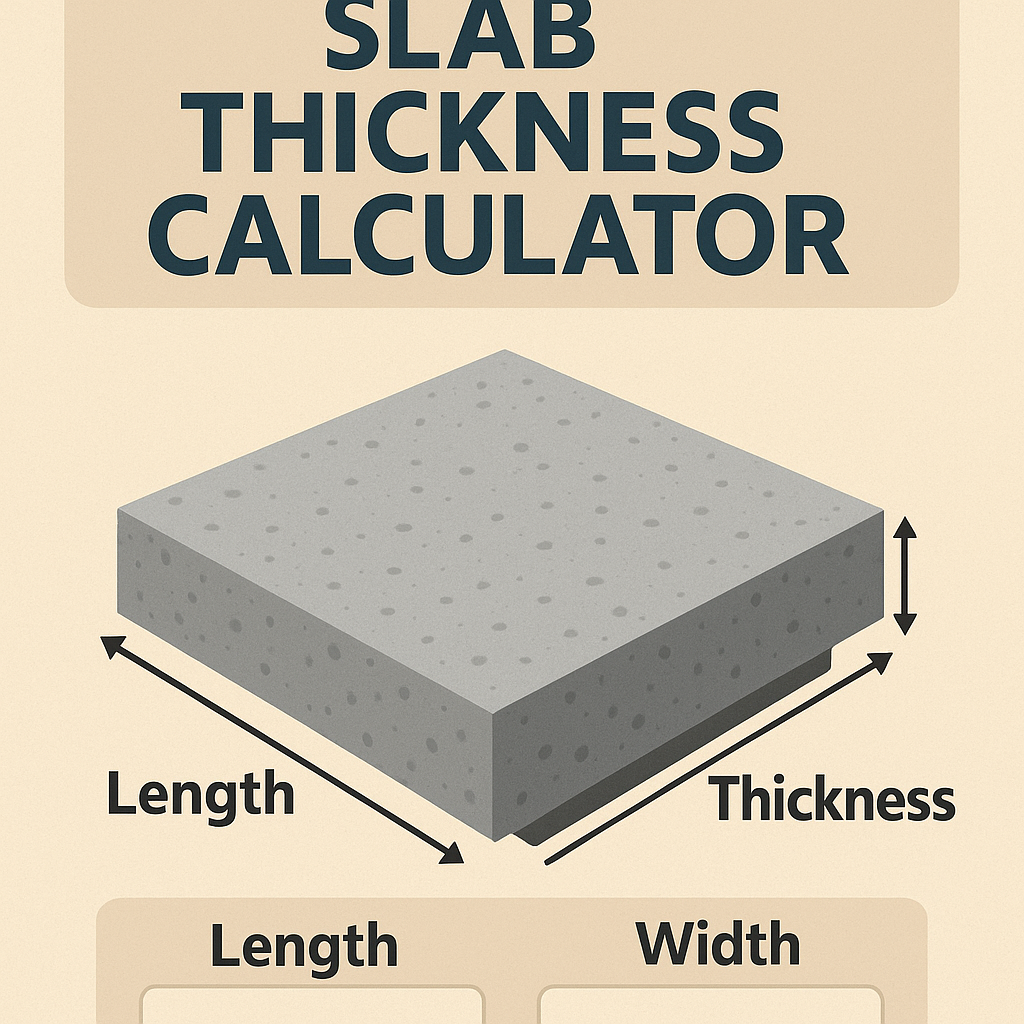

Free Slab Thickness Calculator Online

A slab thickness calculator is an essential tool in construction for determining the correct concrete thickness required for a structural slab. Whether you’re laying a concrete driveway, patio, floor, or foundation, calculating the proper slab thickness ensures structural integrity, durability, and cost-efficiency. At the core of accurate planning is the use of trusted tools like Construction Calculators, which deliver fast, precise estimates and eliminate material waste. This comprehensive guide explores how slab thickness is determined, key input parameters, safety factors, and expert tips to achieve consistent and dependable results for any concrete project.

What Is a Slab Thickness Calculator?

A slab thickness calculator helps builders estimate the required concrete thickness for various construction applications. This calculator simplifies structural planning by using input data such as:

- Slab dimensions (length and width)

- Intended load (live and dead)

- Soil bearing capacity

- Reinforcement type

- Use-case (e.g., residential, commercial, industrial)

Different structures require different slab thicknesses. A garage slab may require 5–6 inches, while a warehouse floor with heavy loads could require 8 inches or more. The slab thickness calculator factors in these conditions to ensure the final result aligns with project requirements.

Why Slab Thickness Matters

Choosing the correct slab thickness is critical. An under-designed slab can crack, settle, or fail over time. Conversely, over-designing wastes material and increases costs unnecessarily. Proper thickness supports:

- Structural load distribution

- Resistance to cracking or warping

- Long-term durability

- Compliance with building codes

Standard Slab Thickness Guidelines

Here are general recommendations for slab thickness by project type:

| Application | Recommended Thickness |

|---|---|

| Sidewalk | 4 inches |

| Residential driveway | 4–6 inches |

| Garage floor | 5–6 inches |

| Commercial floor | 6–8 inches |

| Heavy-duty warehouse | 8–12 inches |

| Concrete foundation | 8–12 inches |

Note that these are guidelines. A slab thickness calculator provides more precise results tailored to your inputs.

Input Parameters for Slab Thickness Calculation

To accurately use a slab thickness calculator, you need the following input data:

1. Load Type and Intensity

Slabs must bear both live loads (vehicles, people, furniture) and dead loads (self-weight, fixed machinery). Heavier loads require thicker slabs.

2. Slab Dimensions

Length and width determine surface area, which affects concrete volume and reinforcement needs.

3. Soil Bearing Capacity

Weaker soils require thicker slabs to distribute loads effectively without settlement or cracking.

4. Concrete Strength

Higher strength concrete (measured in MPa or psi) allows for thinner slabs under the same load.

5. Reinforcement Type

Using rebar or mesh can reduce required thickness because reinforcement strengthens the slab.

6. Project Type

Is it residential, commercial, industrial, or outdoor? The function directly influences slab requirements.

Slab Thickness Calculation Formula

Though slab thickness calculators automate the process, engineers may use formulas to derive slab thickness manually.

For basic applications: $$[

\text{Slab Thickness (inches)} = \frac{\sqrt{\text{Live Load (lb/ft}^2)} \times K}{\text{Concrete Strength Factor}}

]$$

Where:

- KKK = Coefficient based on slab use

- Concrete Strength Factor varies by concrete grade

For a general slab: $$\text{Thickness} = \sqrt{\left(\frac{WL^2}{kEI}\right)} \quad \text{(approximation)}$$

Where:

- WWW = Load

- LLL = Span

- EEE = Modulus of Elasticity of concrete

- III = Moment of Inertia

- kkk = Subgrade reaction coefficient

Note: These are simplified and subject to engineering validation. Online calculators use preset coefficients for common applications.

How to Use the Slab Thickness Calculator

Follow these steps to use the calculator efficiently:

- Enter Slab Dimensions: Provide length and width in feet or meters.

- Specify Load Type: Choose between light residential, heavy vehicle, or industrial loads.

- Select Concrete Strength: Choose standard grades like M20, M25, or enter psi value (e.g., 3000 psi).

- Include Reinforcement Details: Input whether rebar or mesh will be used.

- Input Soil Details: Enter soil bearing capacity if known (typically in kPa or psf).

- Click Calculate: The tool will compute recommended slab thickness in inches or mm.

The calculator may also return total concrete volume using: $$\text{Volume (cubic feet)} = \text{Length (ft)} \times \text{Width (ft)} \times \left( \frac{\text{Thickness (in)}}{12} \right)$$

Slab Volume and Material Estimation

Once you know the thickness, calculating volume helps estimate how much concrete you’ll need: $$\text{Volume (cubic feet)} = \text{Length (ft)} \times \text{Width (ft)} \times \left( \frac{\text{Thickness (in)}}{12} \right)$$

Then calculate cement, sand, and aggregate based on standard mix ratios (1:2:4): $$\text{Cement Bags} = \frac{\text{Volume} \times 1.54}{7}$$

Where:

- 1.54 is the dry volume multiplier

- 7 = Sum of ratio (1+2+4)

You can also use a concrete mix calculator to determine precise material quantities.

Advanced Use Cases

For more complex projects such as post-tensioned slabs or slabs on poor subgrades, you may need:

- Finite element analysis

- Load distribution modeling

- Reinforcement detailing

- Crack control joints

Slab thickness calculators used by structural engineers can incorporate these parameters, but general-purpose calculators serve well for standard applications.

Common Slab Issues from Incorrect Thickness

Improper thickness leads to:

- Cracking due to bending stress

- Settlement in weak soil zones

- Joint failure or separation

- Excessive deflection under load

- Spalling due to insufficient reinforcement

Avoiding these issues starts with using the right tool and inputting correct data.

Tips for Accurate Slab Planning

- Always Overestimate Thickness Slightly: Round up to the nearest ½ inch for safety.

- Use a Reinforced Slab: Even mesh reinforcement reduces required thickness.

- Include Load Distribution Factors: Heavy equipment or point loads require more depth.

- Account for Concrete Shrinkage: Longer slabs need control joints or expansion cuts.

- Check Local Building Codes: Ensure slab thickness meets local engineering standards.

FAQs

What is the minimum slab thickness for a patio?

Minimum 4 inches for light use, but 5 inches is recommended for durability.

Can slab thickness be reduced with stronger concrete?

Yes, high-strength concrete can reduce thickness, but only with proper reinforcement.

Is insulation considered in slab thickness calculators?

Not usually. Insulation (e.g., foam board) is added separately under or over the slab.

What’s the best thickness for a garage slab?

5–6 inches with reinforcement is standard for a single-vehicle garage.

Does soil type affect slab thickness?

Yes. Soft or expansive soils require thicker slabs or subgrade preparation.

Conclusion

A slab thickness calculator is a reliable and efficient way to determine the ideal concrete thickness for your project. By inputting key variables like slab size, load conditions, soil strength, and reinforcement type, the calculator generates a recommended thickness that ensures structural stability and cost-efficiency. Whether you’re pouring a driveway, foundation, or commercial floor, using a calculator helps eliminate guesswork and reduces the risk of failure. For added precision across your project, the Concrete Calculators platform also includes specialized tools like the Epoxy Calculator and Paver Calculator to help estimate coatings, surfaces, and materials with accuracy.

Choose the calculator that fits your specific needs, verify your inputs, and always consult local engineering standards or a licensed structural engineer for critical applications. With the right tools and planning, your concrete slab will be strong, durable, and built to last.