Free Air Compressor Capacity Calculator Online

Understanding the air compressor capacity calculator is critical across the freight, transportation, and logistics industries. From LTL standard rate providers to truckload services and air freight handlers, calculating proper air compressor capacity affects everything from sensitive delivery schedules to value-added services. Whether managing volume-based shipping quotes or improving equipment reliability in a distribution center, using Construction Calculators serves as a central component in service performance and operational efficiency.

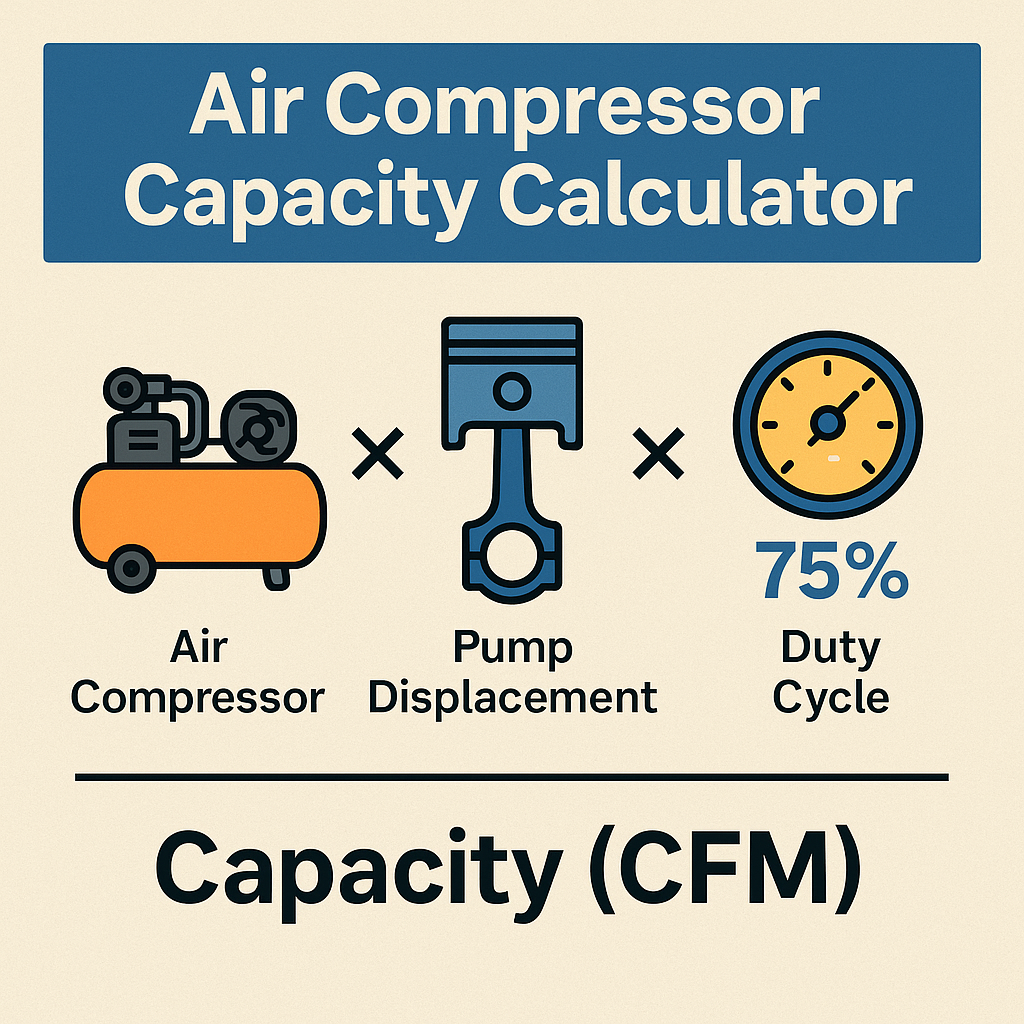

Air Compressor Capacity Calculator

What Is an Air Compressor Capacity Calculator?

An air compressor capacity calculator determines how much compressed air volume an air compressor can deliver, usually measured in CFM (Cubic Feet per Minute). It is essential for estimating tool demand, powering pallet handling systems, and maintaining airflow levels for loading docks, freight line warehouses, and truckload facilities.

This calculator plays a vital role in ensuring operations run at full efficiency, from Old Dominion freight terminals to customer service departments tracking on-time delivery rates. In a sector that thrives on volume, security, and demand, getting capacity estimates right is crucial.

Formula and Key Terms Used in the Calculator

To determine compressor capacity, the most common formula used is: $$[

\text{CFM} = \frac{(P_1 \times V) – (P_2 \times V)}{t \times 144} \times \frac{k}{k – 1}

]$$

Where:

- CFM = Cubic Feet per Minute (airflow)

- P1 = Initial pressure (PSI)

- P2 = Final pressure (PSI)

- V = Volume of tank (in cubic feet)

- t = Time in minutes to fill the tank

- k = Specific heat ratio for air (usually 1.4)

This calculation is widely used in ltl, truckload, and shipping centers that require accurate volume estimates to maintain service continuity and equipment uptime.

Why Air Compressor Capacity Matters in Freight and Shipping

The transportation industry relies on compressed air for various tasks:

- Pneumatic tools used for repairing freight trucks

- Powering automatic pallet stackers

- Operating dry van lift gates

- Maintaining security divider systems

- Supporting sensitive delivery environments

Without an accurate air compressor capacity calculator, claims ratios can increase due to equipment failure, leading to missed rate time targets and failed on-time delivery rate benchmarks.

Applications in Old Dominion Freight and North America Shipping

Old Dominion Freight Line, Inc., operating across North America, uses industrial compressors for running loading bay systems and managing airflow across shipping zones like Alaska, Hawaii, Guam, and the U.S. Virgin Islands.

Whether calculating air rates, volume rates, or service estimates, having the right air compressor capacity ensures that cargo is managed efficiently—especially in high-throughput environments where cube meter rates and volume demands vary daily.

How Capacity Affects Shipping Quotes and Performance

Many freight service providers include air compressor usage in rate estimates. This is especially true for:

- Non-containerized freight requiring manual or air-powered handling

- Dry van shipments where air pressure supports internal systems

- Truckload rate ODFL quoting tools where power requirements must be calculated

If the compressor’s CFM rating doesn’t meet operational demand, it leads to system downtime and delays, pushing out final destination spot timelines and potentially upsetting customer service expectations.

Choosing the Right Air Compressor for Load Handling

Here’s how companies calculate their needs using a capacity calculator:

- Tool CFM Ratings: Add the CFM needs of all tools or systems operating simultaneously.

- Duty Cycle: Consider how long the compressor runs in a cycle (50% or 100%).

- Pressure Range (PSI): Ensure the compressor can reach the required PSI.

- Tank Volume: Larger tanks store more air, useful for peak demand.

- Environment: Cold climates (like Alaska) require higher output ratings.

This process is standard in freight handling hubs, replenishment warehouses, and truckload shipment sites where compressed air supports critical merchandise movement.

Air Compressor Ratings and Volume Capacity by Industry Use

| Application | Required CFM | Required PSI |

|---|---|---|

| Pallet Nailers (manual freight prep) | 2 – 4 CFM | 70 – 90 PSI |

| Pneumatic lifts (dry van gates) | 5 – 8 CFM | 90 – 110 PSI |

| Packaging automation (ltl standard) | 10 – 15 CFM | 100 – 120 PSI |

| Security gate systems | 4 – 6 CFM | 80 – 100 PSI |

| Line marking (rate time indicators) | 3 – 5 CFM | 70 – 90 PSI |

These estimates help shipping managers, tool coordinators, and customer service departments schedule maintenance, request volume rate adjustments, and avoid airflow-related delays in freight operations.

Air Compressor Calculator for Weekend Delivery and Expedited Freight

During weekend delivery services, companies rely heavily on automated systems. An underperforming compressor could:

- Delay expedited services

- Increase claims ratios due to late shipments

- Complicate truck load synchronization

In air rate sensitive delivery routes, like those through Puerto Rico or steamship states, using a calculator ensures equipment like lift systems and pallet clamps function reliably—even when volume shipping demands spike.

Air Compressors in Global Freight Operations

From Old Dominion Freight to global rate providers, the role of air compressors in:

- Securing pallets during shipment

- Supporting non-containerized freight movement

- Maintaining locked-in security zones

is irreplaceable. That’s why service tools like the air compressor capacity calculator are standard in high-performing logistics firms operating across international locations.

FAQs

Q1: What is the most important factor when using an air compressor calculator?

A: Understanding the total CFM demand for your application and matching it to the compressor’s output ensures safe and efficient operations.

Q2: How do I convert my tank volume into cubic feet?

A: Use the formula: $$Volume (ft3)=π×d2×h4×1728\text{Volume (ft}^3) = \frac{\pi \times d^2 \times h}{4 \times 1728}Volume (ft3)=4×1728π×d2×h$$

Where d = diameter in inches, and h = height in inches.

Q3: Do CFM requirements change with altitude or humidity?

A: Yes, atmospheric pressure affects air density, meaning compressors must be recalibrated using the calculator in regions like Guam or highland zones of North America.

Q4: Is it better to oversize or undersize an air compressor?

A: Slight oversizing allows for buffer in high-demand cycles without reducing equipment life or performance.

Integrating Calculators with Shipping and Freight Tools

Advanced systems now integrate the air compressor calculator with:

- Freight rate tools

- Truckload management systems

- Claims tracking software

- ODFL freight quoting portals

This results in more accurate shipping quotes, optimized air rate configurations, and fewer errors due to inconsistent airflow in pallet rate or cube meter calculations.

Real-World Application in Old Dominion Freight Line

Old Dominion Freight Line, Inc. uses air compressor capacity calculators to:

- Ensure tool uptime in regional depots

- Reduce shipping quote errors

- Improve truckload efficiency

- Meet sensitive delivery benchmarks

Whether they are handling volume-based freight or ensuring locked-in security during international cargo transit, air compression plays a crucial role.

Conclusion

The air compressor capacity calculator is a mission-critical tool in today’s logistics, freight, and transportation sectors. Whether managing LTL shipments, preparing for weekend delivery services, or running a truckload operation, precision in air volume estimates translates into smoother operations, fewer delays, and stronger customer service department performance. Tools such as the General Construction Calculators, Stair Calculator, and Welding Calculator help ensure that every measurement is accurate and aligned with operational goals.

Use the calculator not only as a technical guide but also as a planning tool ensuring your warehouse, shipping floor, or freight line has the capacity it needs to run efficiently, every time.