Free Spindle Speed Calculator Online

When it comes to machining and manufacturing, precision is everything. One of the most critical parameters that impacts tool life, surface finish, and cutting efficiency is spindle speed. The spindle speed calculator is an essential tool used by machinists, CNC operators, and engineers to determine the optimal revolutions per minute (RPM) for a cutting operation based on the tool and material in use. By entering the right values into a spindle speed formula, you can minimize tool wear, prevent overheating, and maximize performance especially when using Construction Calculators to guide the process.

In this guide, we’ll break down how the spindle speed calculator works, explore the key variables involved, and walk through formulas that help you get accurate results. Whether you’re working on a milling machine, lathe, or router, understanding spindle speed is vital to machining success.

Spindle Speed Calculator

What Is Spindle Speed?

Spindle speed refers to how fast the spindle (or tool) rotates during a cutting operation. It’s measured in revolutions per minute (RPM) and is one of the key cutting parameters that directly influences the effectiveness of material removal, chip load, and heat generation during the machining process.

Spindle speed varies depending on:

- Cutting material (steel, aluminum, plastic, wood)

- Cutting tool material (HSS, carbide, coated inserts)

- Tool diameter

- Desired surface finish

- Machine type and rigidity

Using an accurate spindle speed calculator ensures proper balance between cutting performance and tool longevity.

Why Is Spindle Speed Important?

Choosing the correct spindle speed affects several critical outcomes in machining:

- Prevents tool failure and premature wear

- Enhances surface finish and dimensional accuracy

- Optimizes cutting forces and chip control

- Reduces heat buildup and thermal distortion

- Improves material removal rate (MRR)

- Saves time and improves overall efficiency

An incorrect spindle speed can result in tool chatter, workpiece burn marks, or even catastrophic tool failure. That’s why a calculator is used to determine the right speed based on material and tool geometry.

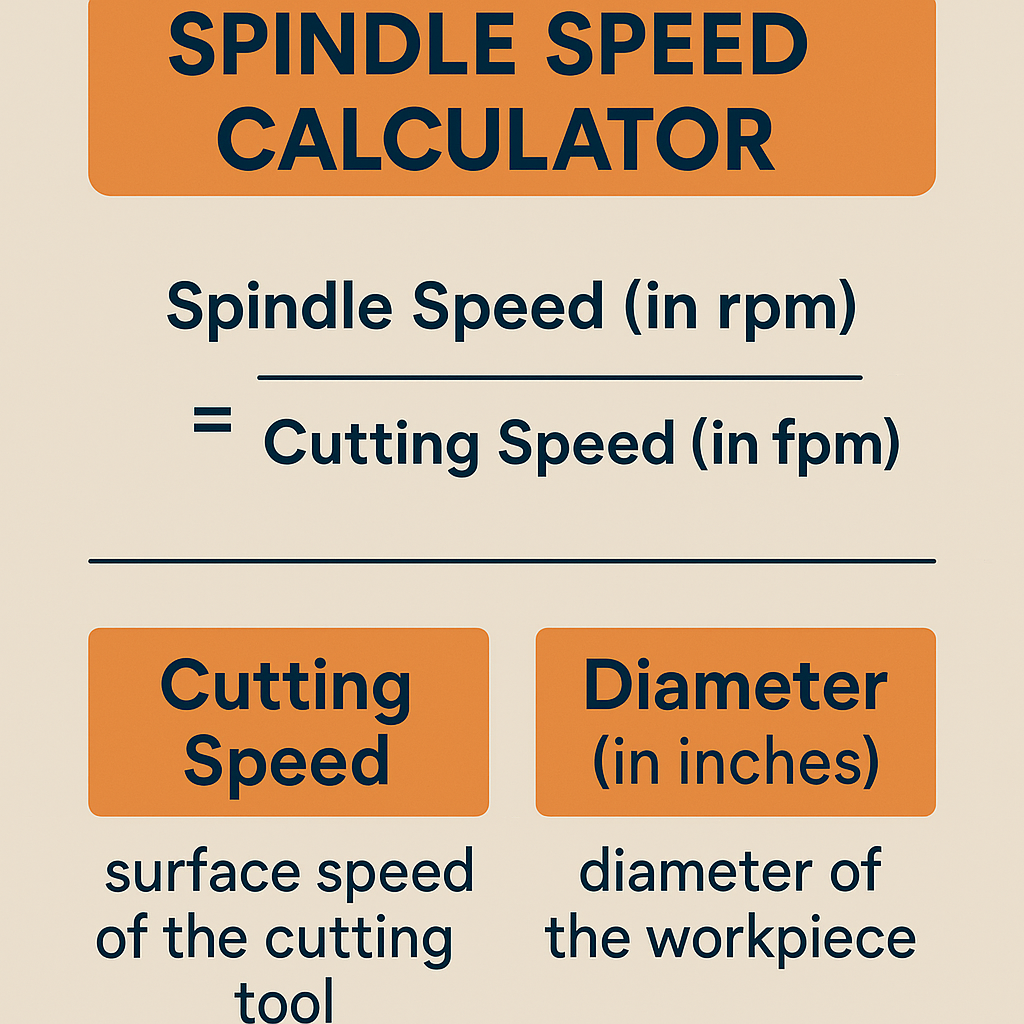

Core Formula for Spindle Speed

The most widely used formula in spindle speed calculation is: Spindle Speed (RPM)=1000×Vcπ×D\text{Spindle Speed (RPM)} = \frac{1000 \times V_c}{\pi \times D}Spindle Speed (RPM)=π×D1000×Vc$$

Where:

- VcV_cVc = Cutting speed (meters per minute or feet per minute)

- DDD = Diameter of the tool or workpiece (mm or inches)

- π\piπ = Pi (approximately 3.1416)

This formula helps calculate RPM based on tool size and the recommended surface speed of the material being cut.

Units Conversion: Metric vs Imperial

Depending on whether you use metric or imperial units, the spindle speed formula adjusts slightly.

Metric Formula (mm, m/min): $$RPM=1000×Vcπ×D\text{RPM} = \frac{1000 \times V_c}{\pi \times D}RPM=π×D1000×Vc$$

Imperial Formula (inches, ft/min): $$RPM=12×Vcπ×D\text{RPM} = \frac{12 \times V_c}{\pi \times D}RPM=π×D12×Vc$$

Where:

- VcV_cVc is the surface speed in feet per minute

- DDD is the tool diameter in inches

Always ensure consistency between units when inputting values into the calculator.

Surface Speed Reference Table

Here’s a quick reference table for typical cutting speeds (VcV_cVc) in meters per minute for various materials and tool types.

| Material | HSS (m/min) | Carbide (m/min) |

|---|---|---|

| Aluminum | 250 | 400 |

| Mild Steel | 30–50 | 100–200 |

| Stainless Steel | 20–30 | 50–100 |

| Brass | 80–100 | 200–300 |

| Cast Iron | 20–40 | 60–120 |

| Wood (soft) | 200 | 300+ |

| Plastic | 150 | 250 |

These values are used as a guide in the spindle speed calculator to determine the optimal RPM.

Example Calculation

Let’s say you’re machining aluminum using a 10 mm diameter carbide end mill. From the reference table, we use:

- $$Vc=400 m/minV_c = 400 \, \text{m/min}Vc=400m/min$$

- $$D=10 mmD = 10 \, \text{mm}D=10mm$$

Plugging into the metric formula: $$RPM=1000×400π×10=40000031.416≈12732 RPM\text{RPM} = \frac{1000 \times 400}{\pi \times 10} = \frac{400000}{31.416} \approx 12732 \, \text{RPM}RPM=π×101000×400=31.416400000≈12732RPM$$

This means your spindle should run at around 12,700 RPM for efficient aluminum cutting using carbide tooling.

Feed Rate and Chip Load

Spindle speed is just one part of the equation. You also need to consider feed rate and chip load: $$Feed Rate (mm/min)=RPM×Number of Teeth×Chip Load\text{Feed Rate (mm/min)} = \text{RPM} \times \text{Number of Teeth} \times \text{Chip Load}Feed Rate (mm/min)=RPM×Number of Teeth×Chip Load$$

Where:

- RPM is spindle speed

- Number of teeth = flutes on your tool

- Chip load = amount of material removed per tooth (mm or inch)

Calculating spindle speed and feed rate together ensures smooth cutting with optimal chip evacuation and finish.

Using a Spindle Speed Calculator Tool

Digital spindle speed calculators allow machinists to input the following:

- Material type

- Tool diameter

- Tool material (HSS, carbide)

- Surface speed recommendation

- Number of flutes

- Desired feed rate or chip load

The calculator then outputs:

- Optimal RPM (spindle speed)

- Feed rate (for CNC programming)

- Cutting time estimate

- Surface finish projection

Most calculators are available online, use JavaScript-based browser tools, and support instant updates when changing parameters.

CNC and Manual Machining Differences

In CNC machining, spindle speed is often programmed using G-code commands like:

$$N = \frac{\pi \times D}{1000 \times V}$$

This line means: set spindle to 12,000 RPM and rotate clockwise (M3).

In manual machining, machinists use dial knobs or variable speed settings, relying more heavily on charts or calculator outputs to make changes.

In both cases, using a spindle speed calculator helps avoid trial-and-error, especially with expensive materials or tools.

Tips for Optimal Speed Control

- Always double-check tool manufacturer recommendations

- Reduce RPM if overheating or tool vibration occurs

- For interrupted cuts (e.g., roughing), use slower speeds

- For finishing passes, use higher RPM for smoother surfaces

- Adjust based on coolant availability and machine rigidity

FAQs About Spindle Speed

Q: What happens if I use too low a spindle speed?

A: The tool may rub instead of cutting, leading to poor surface finish and shortened tool life.

Q: What if I exceed the recommended speed?

A: You risk overheating, work hardening the material, and rapid tool wear or breakage.

Q: Can I use the same RPM for drilling and milling?

A: Not always. Drilling usually uses lower speeds than milling, especially in deeper holes.

Q: How do I calculate speed for turning operations?

A: Use the same RPM formula, but substitute the workpiece diameter for the tool diameter.

Conclusion

Spindle speed is a foundational element in machining performance. The right speed maximizes tool life, ensures precision, and prevents machining errors. A spindle speed calculator simplifies the process, making it easy to input material, tool size, and cutting parameters to receive accurate RPM values. Tools like General Construction Calculators, construction calculator osrs, and the Taper Calculator help machinists make informed decisions with ease and accuracy.

By understanding the formulas and using reliable calculator tools, you can confidently select the right spindle speed for milling, turning, drilling, or routing operations. Whether you’re a professional machinist or a CNC hobbyist, getting the numbers right means fewer mistakes, better finishes, and longer-lasting tools. Let your spindle speed work for you not against you.