Free Taper Calculator Online

A taper calculator is an essential tool for engineers, machinists, and manufacturers who work with conical or tapered components. Whether you’re designing drill bits, shafts, or precision parts, taper calculations are critical for ensuring accurate dimensions, proper fit, and functional results.

From calculating taper angle and taper length to converting between major and minor diameters, this calculator simplifies the complex math involved in machining tapered sections. It ensures every component meets specifications, maintains tolerance, and fits correctly during assembly or operation making it a smart addition to your toolkit of construction calculators.

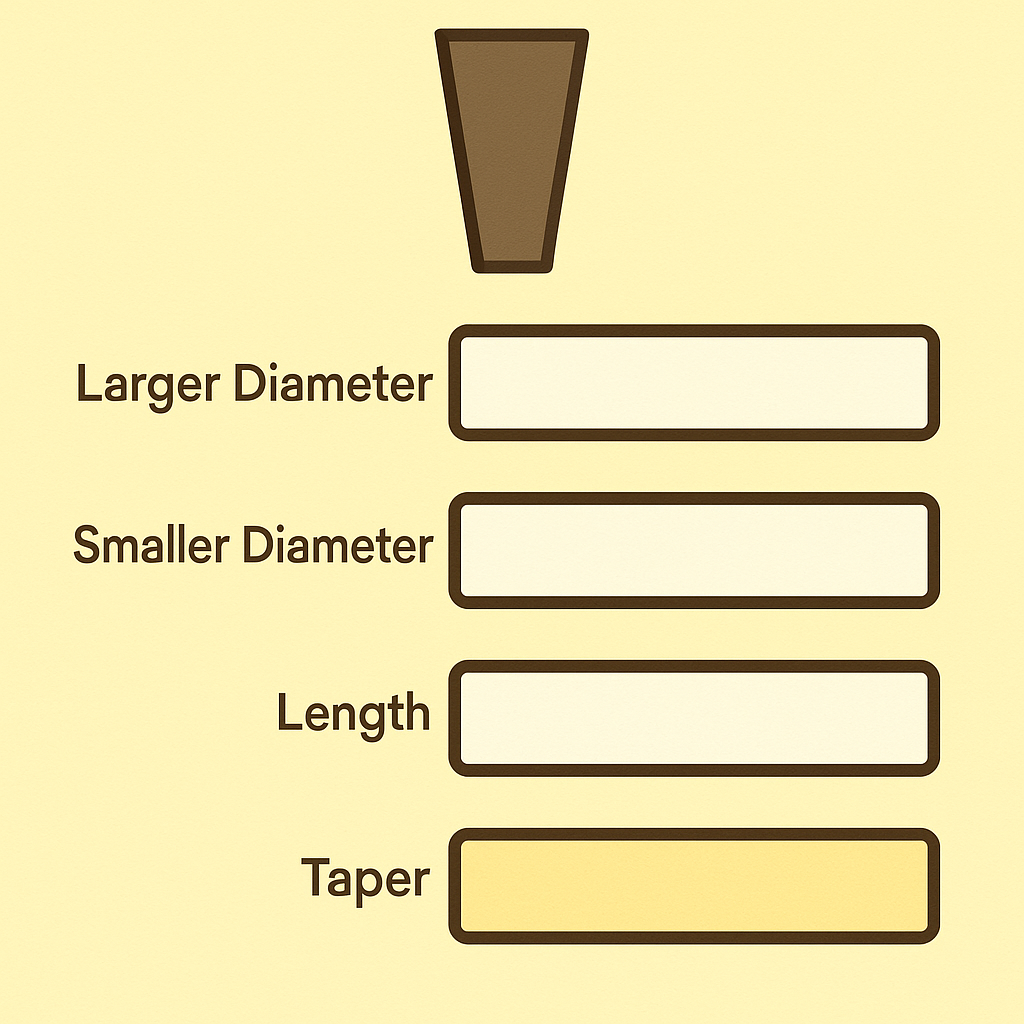

Taper Calculator

What Is a Taper?

A taper refers to a gradual reduction in diameter along the length of a cylindrical or conical object. In engineering and manufacturing, tapers are commonly used to create precise fits between components such as spindles, shafts, and sockets.

Tapers can be found in various industries and applications including drill chucks, Morse tapers, Jacobs tapers, medical devices, and piping systems. Accurate calculation of taper dimensions is crucial for high-performance results.

Why Use a Taper Calculator?

Manual taper calculations require formulas involving diameters, angles, and length, which can be prone to error. A taper calculator helps you:

- Save time by automating taper angle and length formulas

- Prevent measurement mistakes in minor and major diameters

- Ensure compatibility between workpieces and receiving components

- Support precision machining with reliable, unit-based outputs

- Determine taper rate and angle in degrees with exact values

Using a taper calculator simplifies engineering work and improves the accuracy of final components.

Key Taper Terminology

Before using a taper calculator, it’s important to understand the related terms and values:

- Major Diameter: The larger diameter of the tapered object

- Minor Diameter: The smaller diameter at the narrow end

- Taper Length: The overall length from the small to the large end

- Taper Angle: The total angle of the taper, often calculated in degrees

- Taper per Foot or Taper per Inch: Expresses the change in diameter per unit length

Understanding these components helps ensure precision in engineering and toolmaking.

Taper Angle Formula

To determine the taper angle, you can use the following formula: $$Taper Angle (degrees)=tan−1(Major Diameter−Minor Diameter2×Taper Length)\text{Taper Angle (degrees)} $$

$$Taper Angle (degrees)=\tan^{-1} \left( \frac{\text{Major Diameter} – \text{Minor Diameter}}{2 \times \text{Taper Length}} \right)Taper Angle (degrees)$$

$$Taper Angle (degrees)=tan−1(2×Taper LengthMajor Diameter−Minor Diameter)$$

This formula calculates the angle between the taper and its axis, which is essential for tools that require tight tolerances, like drill bits and ground shafts.

Taper Rate Formula

To calculate taper per unit length, use this formula:

$$Taper Rate=Major Diameter−Minor DiameterTaper Length\text{Taper Rate} $$

$$Taper Rate= \frac{\text{Major Diameter} – \text{Minor Diameter}}{\text{Taper Length}}Taper Rate$$

$$Taper Rate=Taper LengthMajor Diameter−Minor Diameter$$

This provides a linear rate that defines how quickly the taper changes over the specified length. It is especially useful when designing components for interchangeable use in different machinery.

How to Use a Taper Calculator

A taper calculator typically requires three input values:

- Major Diameter

- Minor Diameter

- Taper Length

The calculator then provides outputs such as:

- Taper Angle in degrees

- Taper per inch or per foot

- Taper ratio

- Slope of the taper

- Additional dimensions like chord length or segment height (for advanced applications)

These results help in designing accurate taper fits for components that require uniform and precise reduction.

Taper Angle Calculation Example

Let’s calculate the taper angle of a shaft with a major diameter of 2 inches, a minor diameter of 1 inch, and a taper length of 6 inches: $$\text{Taper Angle (degrees)} = \tan^{-1} \left( \frac{\text{Major Diameter} – \text{Minor Diameter}}{2 \times \text{Taper Length}} \right)$$

This means the taper forms a 4.76-degree angle along its axis.

Major and Minor Diameter in Design

The major section and minor section are central to all taper calculations. Designers must choose these values based on the intended application, load capacity, and required fit between components.

A small miscalculation in either the major diameter or the minor diameter can result in a poor connection, excessive wear, or mechanical failure.

Types of Precision Tapers

Different industries use various precision tapers. Some of the most common include:

- Morse Taper: Common in drill presses and lathes for holding tools

- Jacobs Taper: Used in drill chucks

- Brown & Sharpe Taper: Found in older machine tools

- NMTB Taper: Seen in milling machine spindles

- Medical Tapers: Applied in orthopedic components and implant devices

Using a taper calculator helps ensure that these specific taper types conform to industry standards.

Engineering Applications of Taper Calculators

Taper calculators are widely used in:

- Machining tapered shafts and workpieces

- Designing drill bits and tool holders

- Manufacturing medical instruments

- Creating pipe fittings and adapters

- Reducing diameters in rotating components

These applications require not only precise measurements but also quick conversions between inches, feet, and metric units.

Metric vs Imperial Unit Conversions

A reliable taper calculator should allow inputs and outputs in both inches and millimeters. Unit converters help international manufacturers work seamlessly between USA, India, China, and Europe.

For instance:

- 1 inch = 25.4 mm

- 1 foot = 12 inches

- 1 degree = 0.01745 radians

Tools with built-in unit length converters make work easier for machinists in global environments.

Taper Calculator for Pipes and Conical Sections

In plumbing and process engineering, tapers are used in pipe fittings and reduction connections. The tapered pipe thread must match precisely to avoid leakage or pressure loss.

Taper calculators help calculate the outer diameters, internal dimensions, and taper lengths of conical frustums or custom components that are critical in sealed systems.

Taper Length and Component Fit

The specified length of a taper determines how deeply two parts fit together. For proper mechanical operation and tapered component alignment, this value must be accurate.

In a lathe or milling machine, incorrect taper length may lead to vibration, slippage, or tool wear. Calculators allow you to fine-tune these specs for ideal engagement.

Taper Angle and Degrees of Accuracy

When using a taper calculator, precision matters. Small mistakes in decimal places can cause the entire design to fail, especially in high-speed or high-load applications.

Calculations often use angle values like:

- 1:20 taper ratio

- 1:10 for steep tapers

- 1:48 for gentle conical transitions

Even a difference of 0.1 degrees can impact the final machining result or product performance.

Taper Ratio and Practical Use

Taper ratio is another way to describe taper by comparing major to minor diameters. Taper Ratio=Major Diameter−Minor DiameterTaper Length\text{Taper Ratio} = \frac{\text{Major Diameter} – \text{Minor Diameter}}{\text{Taper Length}}Taper Ratio=Taper LengthMajor Diameter−Minor Diameter

This helps standardize taper sizing across tools, drill bits, and custom-manufactured parts. It also makes it easier to work with suppliers and quality control teams.

Real-World Example Problem

You’re tasked with designing a conical workpiece with a major diameter of 1.75 inches, a minor diameter of 1.25 inches, and a taper length of 5 inches.

Step-by-step using the calculator:

- Enter values: 1.75, 1.25, and 5

- Output angle:

$$θ=tan−1(1.75−1.252×5)=tan−1(0.05)=2.86∘\theta = \tan^{-1} \left( \frac{1.75 – 1.25}{2 \times 5} \right)$$

$$θ= \tan^{-1}(0.05) = 2.86^\circθ=tan−1(2×51.75−1.25)=tan−1(0.05)=2.86∘$$

- Result: The taper angle is 2.86 degrees

This fast and precise output is why professionals rely on taper calculators daily.

Benefits of Using a Taper Calculator

- Saves time during complex engineering calculations

- Reduces manual errors when working with angles and diameters

- Supports both imperial and metric unit conversions

- Optimizes fit and compatibility in mechanical assemblies

- Useful for both machining and design professionals

Whether you’re fabricating components in Los Angeles, assembling tools in New York, or manufacturing in South Korea or India, this calculator keeps your specs accurate.

Sample Taper Calculation Table

| Major Dia (in) | Minor Dia (in) | Length (in) | Taper Angle (°) | Taper Rate (in/in) |

|---|---|---|---|---|

| 2.0 | 1.0 | 6.0 | 4.76° | 0.1667 |

| 1.5 | 1.0 | 4.0 | 3.58° | 0.125 |

| 1.75 | 1.25 | 5.0 | 2.86° | 0.10 |

| 3.0 | 2.0 | 8.0 | 3.58° | 0.125 |

Use this table for quick references in your engineering projects.

Conclusion

The taper calculator is an indispensable tool in modern machining, engineering, and manufacturing. Whether you’re working on conical shafts, tapered drill bits, or complex medical devices, accurate taper measurements ensure precision, safety, and functionality. Professionals often rely on tools like the construction calculator OSRS for broader planning tasks, while a ramp calculator can complement taper measurements in accessibility and structural design applications.

From calculating taper angles and ratios to determining proper diameters and lengths, this tool simplifies complex math and boosts design efficiency. As part of a suite of General Construction Calculators, the taper calculator is trusted by professionals across industries. It’s your go-to solution for producing precision tapers and achieving accurate results every time.

Let the numbers work for you use a taper calculator and design with confidence.