Free Torque Wrench Calibration Calculator Online

Accurate torque application is essential in industries ranging from aerospace to automotive, manufacturing to freight. A torque wrench calibration calculator ensures that tools used in precision tightening perform within expected limits. Whether you’re involved in freight services, LTL shipping, or even truckload delivery, a miscalibrated torque wrench can compromise safety, reliability, and performance. This guide explains how Construction Calculators support torque calibration, why they matter in the transportation industry, and how logistics companies across North America and beyond use them for rate estimates, service reliability, and mechanical assurance.

Torque Wrench Calibration Calculator

Why Torque Calibration Is Critical

In any freight or shipping operation, equipment needs to be both strong and safe. Bolts and fasteners that are either under-torqued or over-torqued can lead to delivery failures, damaged pallets, or even accidents. The on-time delivery rate of Old Dominion or any truckload carrier is not only based on logistics and scheduling but also the dependability of the machinery used.

This is where a torque wrench calibration calculator comes in. This tool helps technicians adjust torque wrenches to ensure accurate application according to industry standards. With rising claims ratios in freight lines, especially in steamship states, Puerto Rico, or U.S. Virgin Islands, this calibration calculator plays a silent yet pivotal role in maintaining the integrity of volume-based shipping.

What Is a Torque Wrench Calibration Calculator?

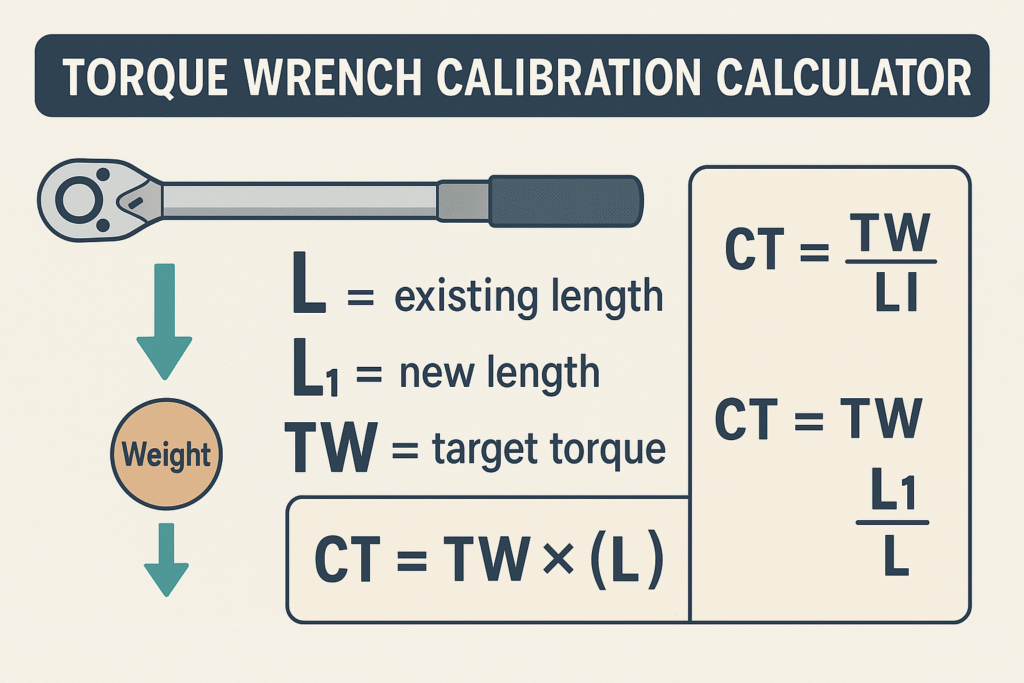

A torque wrench calibration calculator determines the new torque setting required when the handle length or applied force changes. This calculator is essential when modifications are made to a tool for example, adding an extension or adapter—or when environmental conditions affect measurement accuracy.

The basic formula used is: $$\text{New Torque} = \left( \frac{\text{Original Length}}{\text{New Length}} \right) \times \text{Target Torque}$$

Where:

- Original Length is the standard length of the wrench

- New Length includes any extensions or accessories

- Target Torque is the torque required at the fastener

This calculation allows logistics departments, truckload service teams, and freight repair crews to ensure that all fasteners are tightened correctly, especially when servicing vehicles, cargo containers, and volume freight equipment.

How It Applies in Freight and Shipping

Torque calibration might seem technical, but it’s deeply tied to the freight industry. Companies like Old Dominion Freight Line, Inc. and other ltl service providers must frequently maintain and inspect loading equipment, dry vans, security divider mechanisms, and trucks that operate across North America and international locations.

In these scenarios:

- Mechanics use the torque calculator to service axles, frame bolts, and pallet mechanisms

- Engineers verify proper torque settings on locked-in security brackets

- Customer service departments reduce claims ratios by maintaining consistent tightening practices

- Rate estimates and maintenance costs reflect tool calibration accuracy

A single miscalculation could lead to volume damage, delay a sensitive delivery, or result in major safety issues on highways and distribution centers.

Key Benefits of Torque Wrench Calibration Calculators

- Improved Safety: Prevents overtightening or undertightening of critical fasteners on freight equipment.

- Compliance: Ensures all torque values meet international transportation standards.

- Maintenance Accuracy: Helps service personnel maintain fleet vehicles and loading tools with precise calibration.

- Efficiency in Service: Reduces repair time, boosting on-time delivery rates across the freight line.

- Cost Control: Accurate tools reduce equipment damage and improve rate time through proper servicing.

- Enhanced Customer Trust: Lower claims ratios and better service reliability improve client confidence in global freight delivery.

Practical Example

Let’s apply this to a real-world scenario. Assume a technician working for a truckload service provider is using a 20-inch torque wrench to apply 100 lb-ft of torque. They attach a 5-inch extension. The calculator would be used as follows: $$\text{New Torque} = \left( \frac{20}{25} \right) \times 100 = 80 \, \text{lb-ft}$$

In this case, the tool should be set to 80 lb-ft to achieve the intended 100 lb-ft at the fastener. Failure to do this can lead to poor fastening on ltl pallets, cargo doors, or freight container bolts.

Industry Applications Across North America

Across North America, logistics companies, manufacturers, and global freight carriers rely on torque wrench calibration calculators in various departments:

- Customer service departments that manage tool servicing

- Replenishment teams adjusting shelving systems or machinery

- Maintenance departments checking trucks, trailers, and pallet locks

- Tool distribution centers offering value-added services like calibration

- Freight handling teams managing non-containerized freight

Whether you’re managing shipments to Guam, Hawaii, or using weekend delivery services, torque precision ensures every load reaches its final destination spot securely and intact.

Integration with Other Freight Tools

Torque wrench calibration calculators can work in tandem with:

- Forklift load calculators

- Volume rate estimators

- Pallet rate calculators

- Cube meter rate analyzers

- Shipping quote platforms

Together, these tools create a cohesive ecosystem that manages everything from tool accuracy to rate estimates. The combination of mechanical precision and financial forecasting is what keeps the transportation industry functioning smoothly.

Factors Influencing Torque Calibration

Several conditions impact the required torque and its measurement:

- Tool Extensions: Any additional length changes the effective torque.

- Environmental Conditions: Heat, cold, and humidity can affect readings.

- Tool Wear: Old tools may have calibration drift over time.

- Fastener Type: Some materials need torque adjustments.

- Equipment Load: Torque must match equipment stress ratings.

Shipping operators in Alaska, Puerto Rico, or areas with extreme temperature variation must recalibrate regularly to maintain performance standards.

Common Questions and Clarifications

Q: How often should I calibrate my torque wrench?

A: For heavy-duty applications such as freight transport, recalibration every 5,000 cycles or once per year is standard.

Q: Can this calculator be used for digital wrenches?

A: Yes. Whether analog or digital, the formula remains applicable if extensions or changes are made to tool length.

Q: Does torque affect pallet rate efficiency?

A: Absolutely. Improperly torqued fasteners can lead to damaged packaging or shifting loads, affecting delivery schedules and volume estimates.

Q: Is torque calibration part of standard freight service?

A: In value-added services, many providers include torque tool calibration, especially in ltl standard rate contracts.

Advanced Use Cases in Freight and Cargo Handling

Torque calibration isn’t limited to mechanical shops. It’s also used in:

- Aircraft cargo hold fastener checks

- Railway freight car inspections

- Container ship load monitoring

- Freight warehouse racking systems

- Security divider torque confirmation

This ensures that locked-in security systems, air freight hold frames, and steamship container locks perform under extreme pressures and temperature changes. By maintaining precise torque levels, handlers reduce claims, avoid delays, and meet service delivery standards every time.

The Torque-Wrench-to-Shipping Connection

It may seem like a stretch to link a simple tool calibration to freight rates or air rates, but there’s a direct line:

- Improperly torqued equipment increases service downtime.

- Increased downtime affects delivery time, raising cost per mile.

- Raised costs ripple into rate estimates, shipping quotes, and customer satisfaction.

- Higher claims ratios trigger reputation damage and loss of clientele.

- Lost clientele impact truckload rate odfl, ltl rate schedules, and overall revenue.

Thus, the torque wrench calibration calculator contributes directly to freight rate optimization and logistical success.

Conclusion

Whether you’re managing freight shipments, overseeing truckload services, or coordinating deliveries to international locations, a torque wrench calibration calculator helps keep operations tight—literally and figuratively. It ensures every nut, bolt, and bracket is torqued with precision, contributing to safer, more efficient logistics systems across North America and beyond. With added support from the General Construction Calculators, Stair Calculator, and Welding Calculator, accuracy becomes a standard, not a variable.

From improving customer service department workflows to reducing surcharge costs, this simple tool plays a huge role in freight performance. So before your next volume shipment, stop and ask: Is your wrench calibrated?

Formula Reference Table

| Parameter | Description |

|---|---|

| OL (Original Length) | The standard length of the torque wrench |

| NL (New Length) | The length including any extension or adapter |

| TT (Target Torque) | The desired torque to be applied at the fastener |

| NT (New Torque) | NT = (OL ÷ NL) × TT |